.jpg)

.jpg)

Project Duration: 2 Months, Commitment: Part-Time, Year: 2024

.jpg)

Looks-Like Prototype

.jpg)

.jpg)

.jpg)

Research for Choosing a Container Type to Focus On:

Roadside Trash Pickup Analysis:

Picking up roadside trash in Francesca's neighborhood revealed that the most common discarded items include food containers and plastic utensils, fast food soda cups/straws, as well as alcohol and nicotine packaging.

Francesca and her partner, Seamus, mobilized loved ones and neighbors to pick up over 33 large garbage bags full of roadside trash just from their small Rhode Island neighborhood during fall of 2024 and spring of 2025.

Student Interview Result Summary on Disposable Food Container Usage in Daily Life:

University Janitor Interview:

Reveals challenges with recycling success at institutions

.jpg)

.jpg)

.jpg)

.jpg)

Bennett and Francesca collaborated on the vision for the final design product and testing process to achieve it. Bennett sketched the majority of the various packaging structure ideas and Francesca sketched the majority of the packaging texture, surface designs and logos relating to making the packaging identifiable to the user as compostable.

We decided to focus on to-go containers for cold foods like cake.

The goal was to make it out of bio-based materials including edible cutlery.

Chosen Container Type:

Logo Design:

Iteration:

Final:

.jpg)

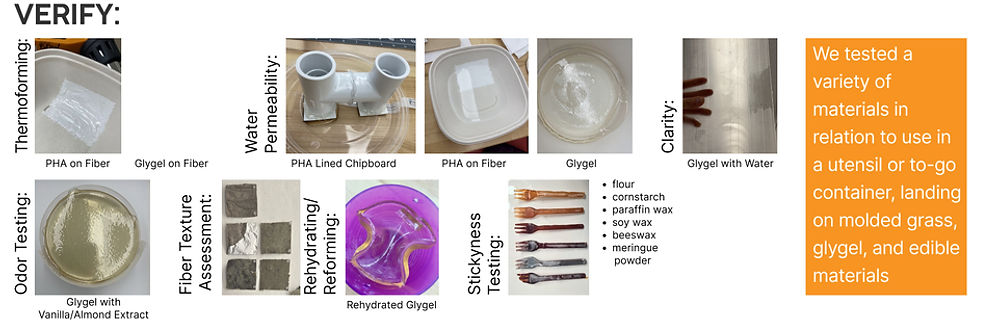

Bennett led investigation on utensil and fiber bottom materials while Francesca led the making of bio-based plastics. Compostable plastic and fiber containers and utensils on the market today require industrial composting to occur and often cannot properly compost in a household backyard compost pile. Bio-based plastic material recipes were inspired by the material libraries of the Rhode Island School of Design Nature Lab and Dr. Manfredi of Brown University.

Bio-Based Plastic Materials Exploration:

Francesca experimented with many batches and recipes for clear bio-based plastics including the following ingredients and results:

![IMG_1962[1]_edited.jpg](https://static.wixstatic.com/media/502e92_1945d762d8e742c586237bc7d5c2db71~mv2.jpg/v1/crop/x_0,y_0,w_2109,h_3000/fill/w_315,h_448,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1962%5B1%5D_edited.jpg)

Base: Kappa Carrageenan Seaweed

![IMG_1965[1]_edited_edited.jpg](https://static.wixstatic.com/media/502e92_c5648e7f5f734544b0c2acd43f89f39b~mv2.jpg/v1/crop/x_0,y_15,w_1890,h_2971/fill/w_285,h_448,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1965%5B1%5D_edited_edited.jpg)

Base: Agar Seaweed

![IMG_1970[1]_edited.jpg](https://static.wixstatic.com/media/502e92_3752b05ad8654afa9c8c00ae901f110b~mv2.jpg/v1/crop/x_107,y_0,w_2036,h_3000/fill/w_304,h_448,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1970%5B1%5D_edited.jpg)

Base: Potato Starch, Gelatin

FILTER

Chosen Material: "Glygel"

![IMG_1975[1]_edited.jpg](https://static.wixstatic.com/media/502e92_c60da757000c4d1da8964d8f29bf83ea~mv2.jpg/v1/fill/w_476,h_640,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1975%5B1%5D_edited.jpg)

Recipe includes gelatin, vegetable glycerin and water

Based on storage conditions, it was determined that Glygel has reasonable resistance to humidity. However, through water permeability testing, it was found that submerging Glygel in water causes it to lose its hardness and rehydrate into a softer, more fragile version of its form. This showed that Glygel would be best used for containing relatively dry foods.

However, rehydrating a dry sheet of Glygel by soaking it in water allowed it to be pressed into a mold and formed with higher fidelity. A heat gun on its lowest setting also proved useful in helping the re-formed material to cure faster on the mold.

.jpg)

.jpg)

.jpg)

Fiber Materials:

Through conversations with experts in the compostable fiber packaging industry and by reviewing material samples from various companies, we learned that rather than relying on unsustainable farming methods for bamboo or sugarcane as conventional compostable fiber containers do, the future lies in creating fiber from locally grown grasses that support healthy ecosystems and sequester carbon from the atmosphere.

MAKE

![IMG_1248[1]_edited.jpg](https://static.wixstatic.com/media/502e92_aa11eb1022b44515bde6f4a78736c92a~mv2.jpg/v1/crop/x_9,y_0,w_2852,h_2250/fill/w_301,h_234,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1248%5B1%5D_edited.jpg)

![IMG_1344[1]_edited.jpg](https://static.wixstatic.com/media/502e92_4ef0c928a2b04c97a4d26582e45cd602~mv2.jpg/v1/crop/x_150,y_0,w_2611,h_2250/fill/w_272,h_234,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1344%5B1%5D_edited.jpg)

Bennett led fiber recipe explorations and mold making. Francesca assisted with grass collection and blending, mold 3D printing and grass mold pressing.

About 20 prototypes were molded, exploring different grass fiber-based recipes to see what binders and fillers were needed to make “looks-like” and “works-like” prototypes, as well as what natural dyes can effectively be used in the mixture. Rice paste from Calrose white rice proved most effective as a binding agent.

Edible Utensils:

![IMG_1112[1]_edited.jpg](https://static.wixstatic.com/media/502e92_064e1c65d3204c10a57a42d969a73985~mv2.jpg/v1/fill/w_248,h_123,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1112%5B1%5D_edited.jpg)

![IMG_1760[1]_edited.jpg](https://static.wixstatic.com/media/502e92_bcca3145d9b147528783a7f605d069a4~mv2.jpg/v1/crop/x_0,y_278,w_2758,h_1815/fill/w_248,h_163,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1760%5B1%5D_edited.jpg)

![IMG_1986[1]_edited.jpg](https://static.wixstatic.com/media/502e92_377783b1c71f48efa2c9323a7310d105~mv2.jpg/v1/crop/x_54,y_0,w_1551,h_2817/fill/w_316,h_574,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1986%5B1%5D_edited.jpg)

To refine the edible utensil concept for use, Bennett experimented with flour, cornstarch, paraffin wax, soy wax, beeswax, and meringue powder as coatings to reduce stickiness. Francesca assisted with fork casting and shaping as well as facilitated user testing. A variety of molding processes were explored, and different forks were made at different thicknesses so it could be determined what the appropriate amount of material would be in continued development.

Results from testing determined that meringue powder was the most effective finish and that thinner forks were preferable for eating (thicker ones consisted of too much material for practical eating).

.jpg)

.jpg)

.jpg)

Glygel Lid Proof of Concept

Looks-Like Prototype with Model Cake

![IMG_1994[1]_edited.jpg](https://static.wixstatic.com/media/502e92_cd0ae4c71a8f476a94bce92cefd16a8f~mv2.jpg/v1/fill/w_456,h_342,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_1994%5B1%5D_edited.jpg)

Glygel Lid Mold Process

(Limitations existed without industrial machinery)

Glygel Proof of Concept Lid on Fiber Bottom Prototype

Final Looks-Like Prototype containing a slice of homemade lemon cake paired with a mildly lemon/citrus flavored fork

.jpg)

User polling on what materials seem compostable shows that common compostable plastic products are not easily identifiable as compostable, while the materials Francesca and Bennett created for this project are.

Items labeled in green text are compostable. Tallies on sticky notes represent user votes for compostability.

.jpg)

Successful composting testing of Glygel

REFLECTION:

It is important when creating a product designed to impact the environment positively at the end of its life to consider how sustainable the practices are in sourcing the necessary raw materials.

For the clear Glygel lid, gelatin is made of the bone, skin, and connective tissue of animals, typically a byproduct from the meat industry. While it is good to make use of industry byproducts instead of landfilling them, the meat industry as a whole has a myriad of negative impacts on the environment. In an ideal world, a plant-based, home-compostable, clear bioplastic would become more used in the packaging industry. Perhaps that could be Kappa Carrageenan, Agar-based bioplastics, or PHA, which are rising in popularity and will hopefully become more affordable over time. Glygel just had the best properties for us to work with given the timeline and manufacturing resources available to us during this project exploration.

Vegetable glycerin is typically made from soybean oil, coconut oil, or palm oil. Farming all of these crops can have a negative impact on the environment due to general agriculture industry practices that cause deforestation, pollution, biodiversity loss, and soil depletion. The vegetable glycerin used in this project was made from palm oil, the industry which is, unfortunately, the most known for its negative environmental impacts, including habitat loss for endangered species (World Wildlife Fund, 2024). Ideally, palm oil would be avoided in bio-based plastic production, and any crop associated with its production would be grown more sustainably.

The edible forks also made out of sugar, have the same sugarcane agricultural practices as a concern. In addition, the main ingredient of meringue powder is pasteurized egg whites, so they are not appropriate for vegan consumers. The egg industry also has some negative impacts on the environment, so sourcing meringue powder made from eggs from poultry farms that practice more sustainable methods would be recommended. Manufacturing a vegan option would be positive as well.

Thank you to Bennett, the MADE Faculty and the RISD Nature Lab!

.jpg)

.jpg)

.jpg)

.jpg)